Feature

- VISIT YAMAGATA

- Feature

- [Feature] Karube Zori! Making Traditional Sandals by Hand

[Feature] Karube Zori! Making Traditional Sandals by Hand

Even as times change, handcrafts that are close to our lives never fade.

One such company is Karube Zori, a long-established shop in Sagae City, Yamagata.

Zori are traditional footwear that become more comfortable and familiar the more you use them.

This time, we tried our hand at making sandals at Karube Zori!

1. What is Karube Zori?

Karube Zori, which has its workshop in Sagae City, Yamagata Prefecture, is a long-established sandal manufacturer founded in 1913.

In the field of “hand-woven sandals,” where each pair is hand-woven by artisans, they hold approximately 95% of the national market share.

Established over 110 years ago.

While continuing to maintain the same methods, it continues to be loved today in a form that fits into modern lifestyles.

2. Special craftsmanship of sandals

The appeal of Karube zori lies in their beauty and comfort.

This is made possible by the utmost attention to raw materials and the uncompromising handiwork of artisans in every process.

The “Toyokuni” variety of rice straw, suitable for making sandals, is planted by hand in collaboration with farmers.

In autumn, the straw, which has become prone to falling over, is raised up and carefully harvested by hand or using a binder.

The harvested straw is dried naturally on a stake and then carefully threshed.

By further aging it in a storehouse, it is finished into the core material of the sandals, which has a glossy finish and softness.

Bamboo bark is also an important material.

The bamboo is harvested deep in the mountains, filling backpack baskets, and after drying and fumigation, only the highest quality bamboo bark with few spots is used.

They also sort the sandals by color and texture, making them aesthetically pleasing.

The dried straw is cut out one by one at the nodes, and the craftsman trims it down, checking the length and thickness with his fingertips.

Meanwhile, the bamboo skin is softened by soaking it in warm water and then carefully cut into strips using a skin splitter.

Each step involved wisdom and experience to make the most of the materials.

During the knitting process, each pair is carefully knitted by hand.

It is a delicate process that takes even a skilled craftsman about an hour to knit a pair.

The last step is “sun drying”.

Hanging it under the eaves and letting it dry slowly in the natural wind and sun makes it stronger and more lustrous.

Sandals that are dried in the cold winter wind are called “cold sandals” and have a particularly beautiful texture.

At the factory in Sagae City that we visited for this article, the entire process is carried out, from pressing after sun-drying to finishing.

When you enter the factory, you’ll see lots of sandals!

It’s amazing that they’re all hand-knitted.

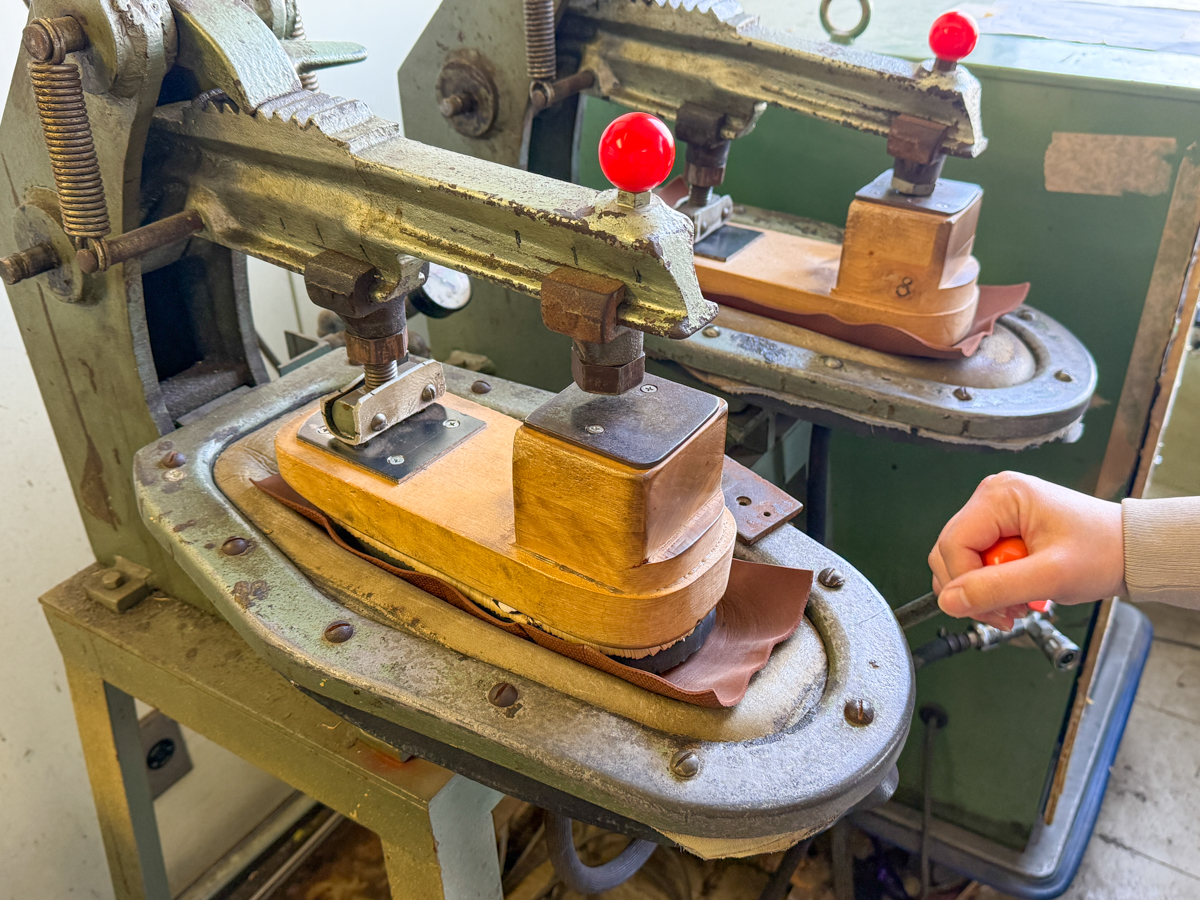

The woven sandals then go through a process called pressing, where they are pressed to set their shape.

After placing the sandals in a mold and heating them at high temperature, they are lined up in a hydraulic press and squeezed all at once.

We will finish it to a moderate thickness.

The difference is obvious when you compare the sandals before and after pressing!

The plump, hand-woven sandals are well-formed and have a neat and beautiful appearance.

In this experience, you will use these compressed sandals as a base for finishing touches such as attaching the thongs.

The challenge is to create a one-of-a-kind pair of sandals with your own hands!

3. Zori-making experience

Now it’s time to start the zori-making experience!

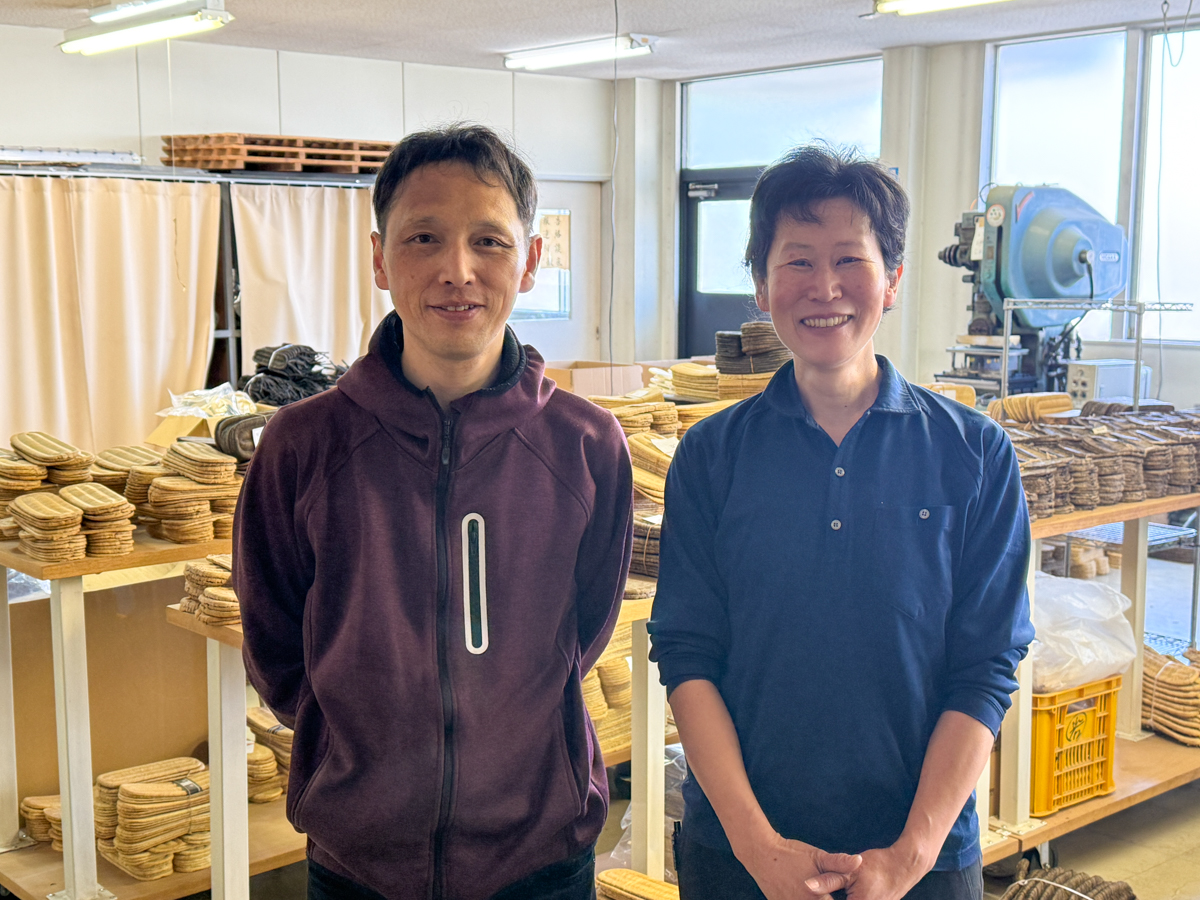

First, President Karube-san gave us an overview of Karube Zori.

Karube Zori products are still used in festivals across the country (Aomori Nebuta Festival, Asakusa Sanja Festival, Kishiwada Danjiri Festival, etc.), and are also used in NHK’s historical dramas and as the sandals worn by the three top ranking referees in sumo wrestling.

This is proof that the high quality and craftsmanship of Karube Zori is widely recognized.

① Attaching the sandal

Now that you have gained more knowledge about Karube zori, the first thing to do is choose the size of the zori to fit your feet.

After deciding on the size, you can choose the thong.

This may be the most exciting moment of the zori-making experience.

This time, I chose this pattern from the colorful thongs available.

All the materials are provided, so you can try it right away without having to bring anything with you.

First, place the pattern on the surface and mark the holes with a kujiri (a tool for making holes).

Being careful with your hands, poke the hole for the thong through.

Put the thong into the tsupo (a tool used to thread the thong through the hole),

Push it firmly into the hole you just made.

This feeling is quite difficult and I can’t really tell if it’s in or not!

You just pull it straight through, and it feels really good when the thong goes through the sandals and comes off.

Next, place the pattern on the toe side and make a mark.

Be careful not to prick your hand.

The white string is inserted into the bottom of the sandals using a kuji.

Apparently this insertion process is the most difficult part for everyone.

Apparently it feels more like sliding it in rather than stabbing it in, which is certainly difficult!

During the soba work, Mr. and Mrs. Karube exclaimed, “Good job, good job!”

“It feels good,” he said, providing careful support.

What impressed me was that I was able to concentrate on my work in a friendly atmosphere.

Once inserted, securely tie the metal fittings and string on the back.

The next step is to sew the sandals together.

This was quite a laborious task!

It was the first time I’d ever used a thick, long sewing needle…

Press firmly with the needle holder.

I struggled at first because I didn’t know where to insert the needle or where it would come out…

However, little by little, I had more and more moments when I felt like, “Oh, maybe that was good!”, and each time I felt a small sense of joy.

Before you know it, you’ll be completely hooked.

It was an experience that allowed me to experience firsthand the difficulty and fun of making sandals.

After some post-processing to prevent the thongs from loosening, both the left and right sandals are complete!

It turned out so well that even I was surprised.

It’s nice to see it take shape like this.

This completes the “attaching of the thong.”

The process is exactly the same as that of a craftsman, but even just this one pair of shoes made me realize the amazing skills of the craftsmen.

② Attaching the base

Next, the “base material attachment” is carried out in the adjacent workshop.

Wear an apron and arm covers!

First, the craftsman showed us how to make it.

Use a brush to apply the glue thinly and evenly.

Apparently, if you apply the glue too thickly, it will take longer to dry.

It’s actually quite difficult to do it yourself…

We attach the sandals we worked on earlier to the soles.

Let the glue dry for about 30 minutes and then press the pieces together.

Once attached, use a crimping machine to firmly press the pieces together.

Remove from the crimping machine and it’s done!!!

I put a tag on it and put it in a bag.

Resisting the urge to use them right away, I let the sandals dry thoroughly overnight.

The next morning, I tried them on and was surprised at how comfortable they were!

The sandals are made with cushioning material, so they fit gently to your feet and don’t cause the pain that is common with other sandals.

This is perfect for everyday use.

I felt like I grew more attached to them every time I wore them.

This “Karube Zori” sandal making experience is held every winter (November to March).

If you are interested, please feel free to contact Karube Zori.

*Some of the photos in this article were provided by Karube Zori.

4. Message to VISIT YAMAGATA readers

Finally, Mr. Karube, President and CEO of Karube Zori, gave a message to everyone reading VISIT YAMAGATA.

“Karube Zori is the only company in the country that makes hand-woven sandals using natural materials.

In hot weather, it feels great to wear them barefoot.

Bamboo bark also has antibacterial properties, so even if you have never worn them before, we encourage you to experience their comfort.

Please try your hand at making your own one-of-a-kind sandals.”

Detailed information

-

Karube Zori

51 Central Industrial Park, Sagae City, Yamagata Prefecture 991-0061

☎ 0237-77-5322

******************************[Zori making experience]

November to March every year

At VISIT YAMAGATA Activities

Applications are scheduled to begin in October 2025

![[Activity] Mt. Kumanodake & Okama in Winter! Go up Zao in snowshoes [2026][OPEN]](https://www.visityamagata.jp/wp/wp-content/uploads/2022/03/お釜トレッキング_お釜01.jpg)

![[Activity] Snowshoe Trekking at Zao! Snow Monsters with a guide [2026][OPEN]](https://www.visityamagata.jp/wp/wp-content/uploads/2021/01/o8889187c95ca4d973d8cf0c7a6b37d8d_64634470_210122_0012.jpg)

![[Feature] Satoya! Make your own Japanese Sweets](https://www.visityamagata.jp/wp/wp-content/uploads/2025/11/satoya.jpg)

![[Feature] Bed & Vegetable Kahoku! Experimental Hotel](https://www.visityamagata.jp/wp/wp-content/uploads/2025/08/BV.png)

![[Activity] Apple Picking! Kosaku Orchard in Asahi Town](https://www.visityamagata.jp/wp/wp-content/uploads/2025/10/幸作りんご_aita-13.jpg)